Our Story

CCP Gransden is a UK-based family business with a rich engineering heritage.

We are constantly advancing, successfully supporting countless projects right through from concept to commercialisation, across a diverse range of ventures.

Over many years we have accrued a significant amount of know-how.

A BRIEF HISTORY OF CCP GRANSDEN

In 1894, Augustus Warren Hamilton, known as "Gussie" to his friends, was a young Belfast engineer sailing routes across the North Atlantic with the Ulster Steamship Company. After getting engaged and with a family on the way, he wanted to create a more secure future. So, Gussie left his job, returned to his hometown, borrowed some money, and teamed up with a friend to establish 'Hamilton and McMaster Engineering Co.'

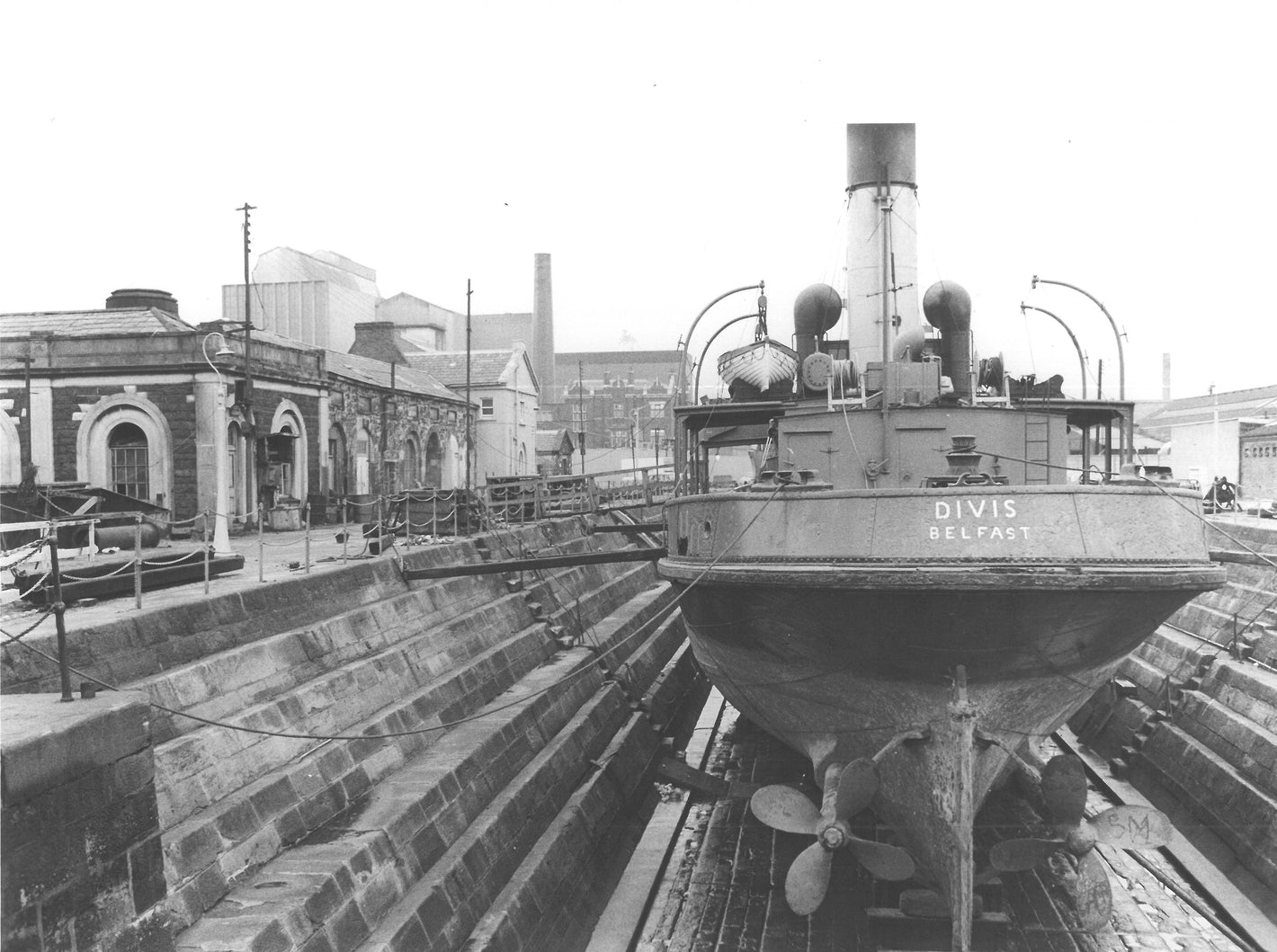

The business was based at Princes Dock Street, at the heart of the growing community living and working in the bustling cobbled streets of Sailortown in Belfast. At this time, Belfast was the premier shipbuilding centre of the world, and the firm took on general engineering and ship repair work in the docks. After five years of graft, the team had managed to pay off all debts in full plus interest.

The business continued to develop.

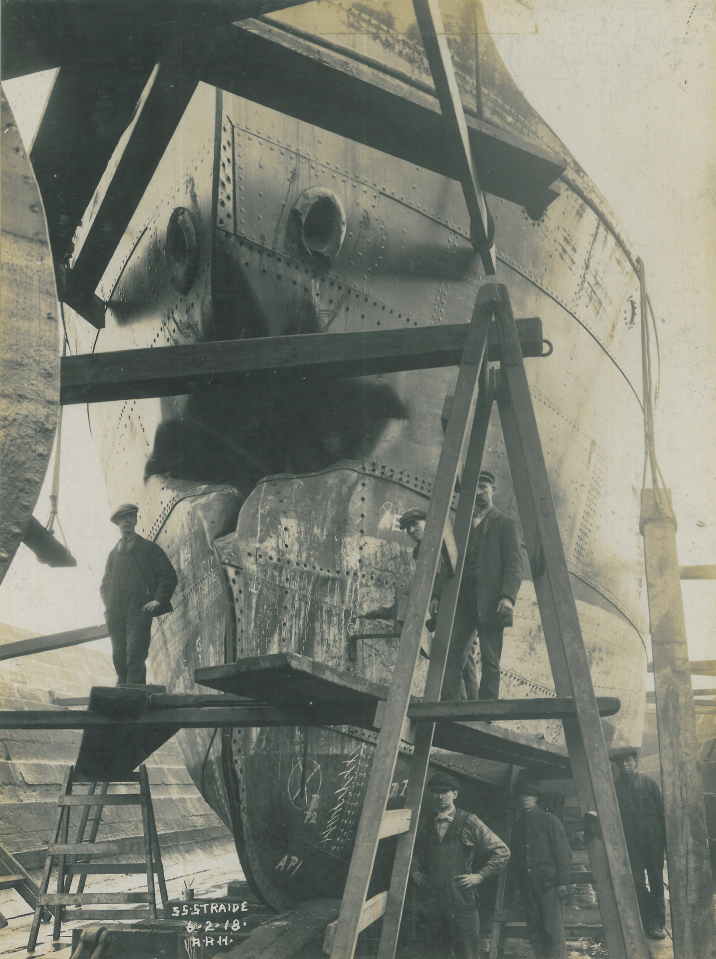

[Below] The SS Straide is repaired after surviving damages from a German naval mine during World War 1.

Numerous challenges were faced.

The First World War saw the company tasked with essential admiralty repairs, and rapidly working to busy schedules with a notably bigger workforce.

In the following years the post war recession brought difficult conditions. With the shipyards less busy men would queue for any limited work they could get, and in some cases, this was for only one or two hours in a day.

Notably, in the early 1930's at the height of the Great Depression, there were several periods when managerial staff took no salary in order to pay for materials, succesfully keeping the business running through the turbulent markets, and avoiding collapse like so many others.

During The Second World War the business was once again listed as a key 'reserve occupation'. In 1941, the premises narrowly survived major fires amidst the Belfast Blitz, managing to carry on essential work throughout the surrounding destruction. Over the course of the war, in addition to their industrious day-to-day work many employees also volunteered their limited free time in various units such as the Home Guard, Police and Fire Services, RNLI, and others.

As had similarly been the case years before, despite employing over 400 extra labourers during the war period the company was not permitted to claim any profits and then suffered in the post war recession.

Later, as The Troubles began, the company and its employees faced more tough times. Sadly the community around Princes Dock Street witnessed a number of merciless bombings.

As time went on major changes to the wider shipbuilding industry presented a key hurdle.

Core policies of upholding sound engineering workmanship and continuous innovation, have helped the company be adaptable through historical challenges, taking on a wide variety of interesting projects.

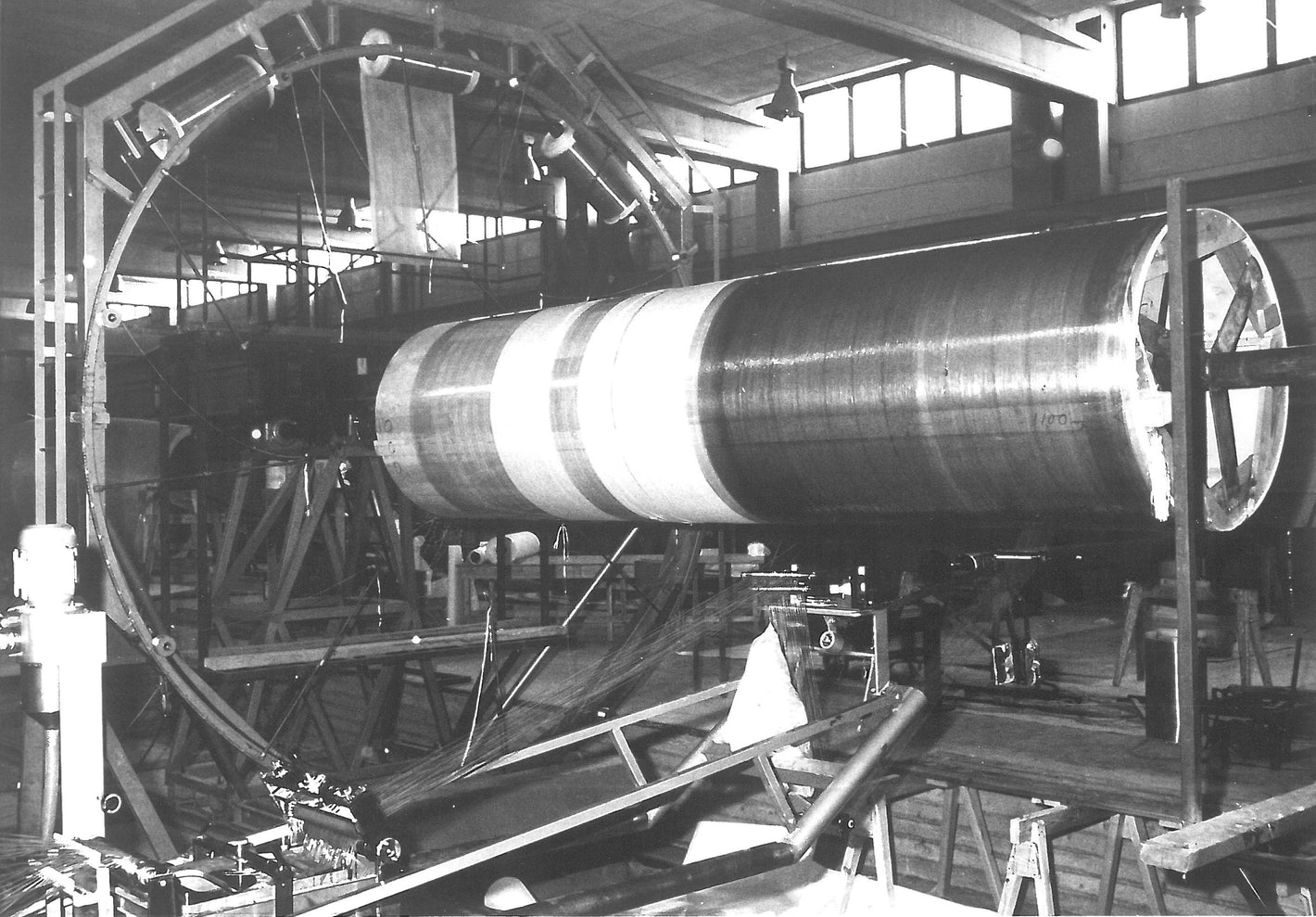

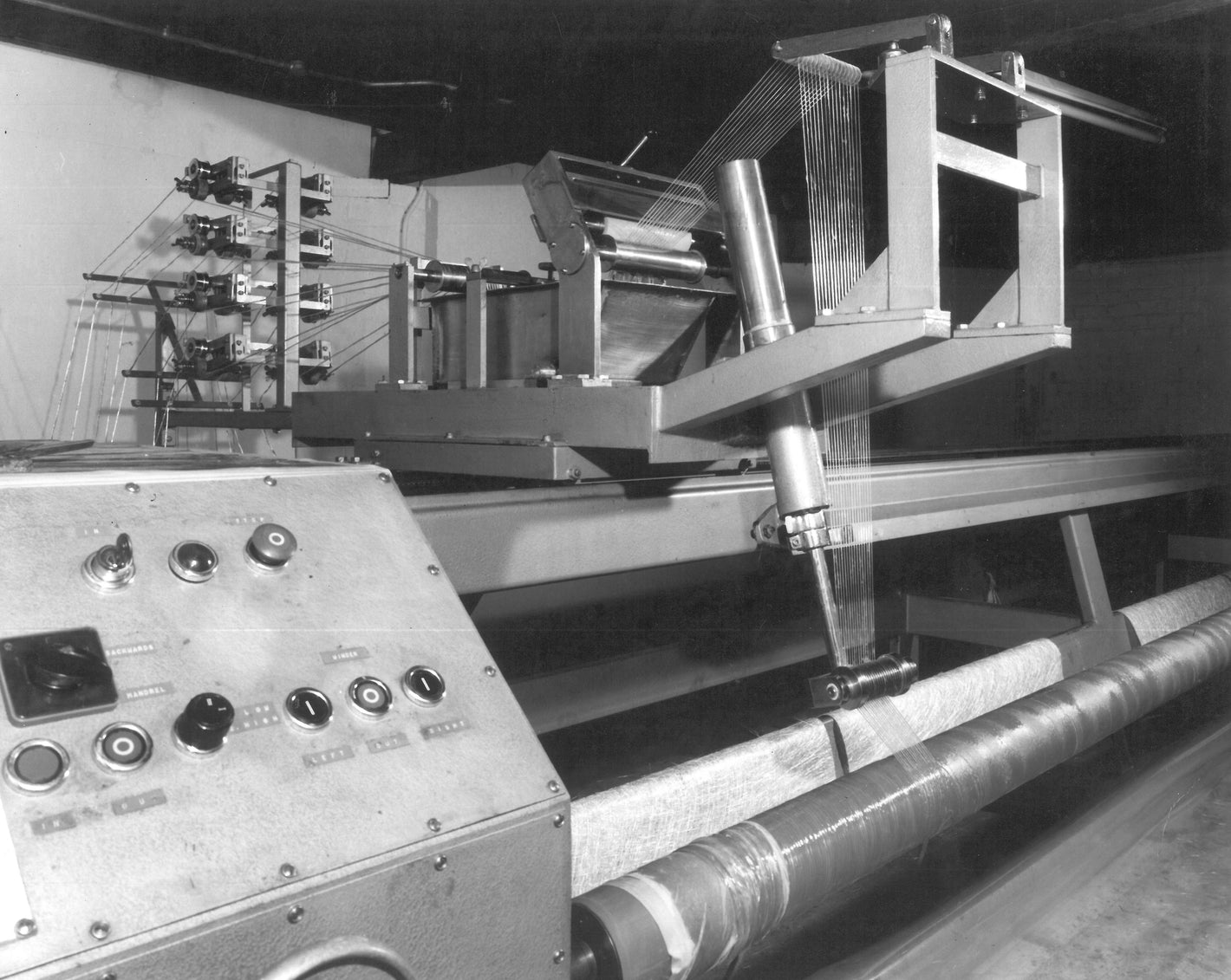

The company diversified in the 1960's establishing 'Corrosion Control Plastics', and was one of the first in the region to realise the opportunities with modern composites as the field rapidly developed.

Around this time the business moved to new larger premises in Ballygowan, just south of Belfast.

As the corrosion resistant plastics element of the business grew, the company name evolved with it. Corrosion Control Plastics led to the 'CCP' acronym, with 'Gransden' added when the firm acquired Gransden (BiChem).

Many firms came and went; selling-out, moving abroad, or succumbing to changing markets.

CCP Gransden innovated.

A linked spin out is CCP Gransden's sister company Hamilton Erskine who manufacture 'Tecdur' blast / ballistic protection solutions, based at the same location in Ballygowan.

60+ YEARS MANUFACTURING COMPOSITES

CCP Gransden have made several major technological investments, growing a sophisticated facility which boasts potentially the UK's largest selection of advanced composites manufacturing processes in-house.

WE ARE PREPARED FOR THE FUTURE

Need an experienced partner for your composites projects?