Engineering Services

To ensure that our client's individual needs and goals are achieved, we prefer working closely with our customers from the start to select the most appropriate solution.

We can provide our clients in-depth guidance and support with material and process selection. We are well-placed to do this with our extensive in-house capability.

Our early involvement can support increased component efficiency, weight reduction, parts count reduction, cycle time reduction, and cost reduction.

MEASURED-&-MANAGED MANUFACTURING

- Enterprise resource planning

- An extremely capable system which we have specially optimised for our facility

- Full product traceability

- Accurate pricing

- Shopfloor management

- Intelligent analytics

- Jet Reports / PowerBI

- Integrated CRM (Customer

Relationship Management) - Full virtual factory tour available

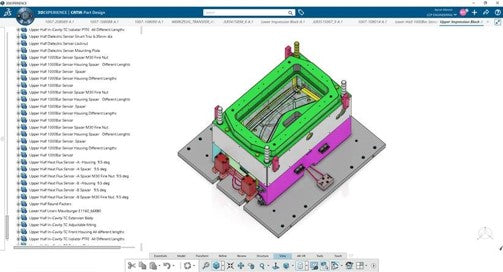

CAD & PROJECT MANAGEMENT

We use the latest CATIA and 3D Experience packages.

Our engineering team are equipped with good software and stringent processes ensuring secure, efficient, and reliable design and manufacturing.

SIMULATION TO SUPPORT DESIGN AND

PERFORMANCE VALIDATION

As an example, in our pressure vessel work we have used Abaqus for:

•Failure analysis and strength

prediction

•Optimization to improve weight, strength and lifetime (refuelling, temperature effects, etc)

•Accurately predict behaviour of

filament wound pressure vessel by transferring the filament winding data into FEA

LEADING MATERIALS INSIGHT

Because CCP Gransden has one of the UK’s largest selections of advanced composite manufacturing processes available at our facility, we are seen as a key partner by global material suppliers. This partnership enables CCP Gransden to have access to new and prototype materials before they are available on the market. It also allows us access to additional technical support from material suppliers when working on client solutions.

CCP Gransden has the in-house capability to complete projects in any stage; from the design and manufacture of tooling for prototype component manufacture, right through to optimising TAKT times for high-volume production. Championing our dynamic capacity allows us to deliver solutions to a wide array of specialist projects. All of these projects are driven forward by our reliable and committed team who have a demonstrated history of high-quality workmanship.