Example Applications

We manufacture high value composite products for a range of industry sectors. We are trusted by notable global customers.

MULTI-SECTORAL SOLUTIONS

-

STARStreak Lightweight Composite Launch Canisters and Optical Housings for Thales

Thales' STARStreak is the fastest short-range surface-to-air system in existence.

-

Components for the Rolls-Royce UltraFan®

Multiple composite parts are employed in the world's largest and most powerful jet engine (which can run with 100% sustainable fuel).

-

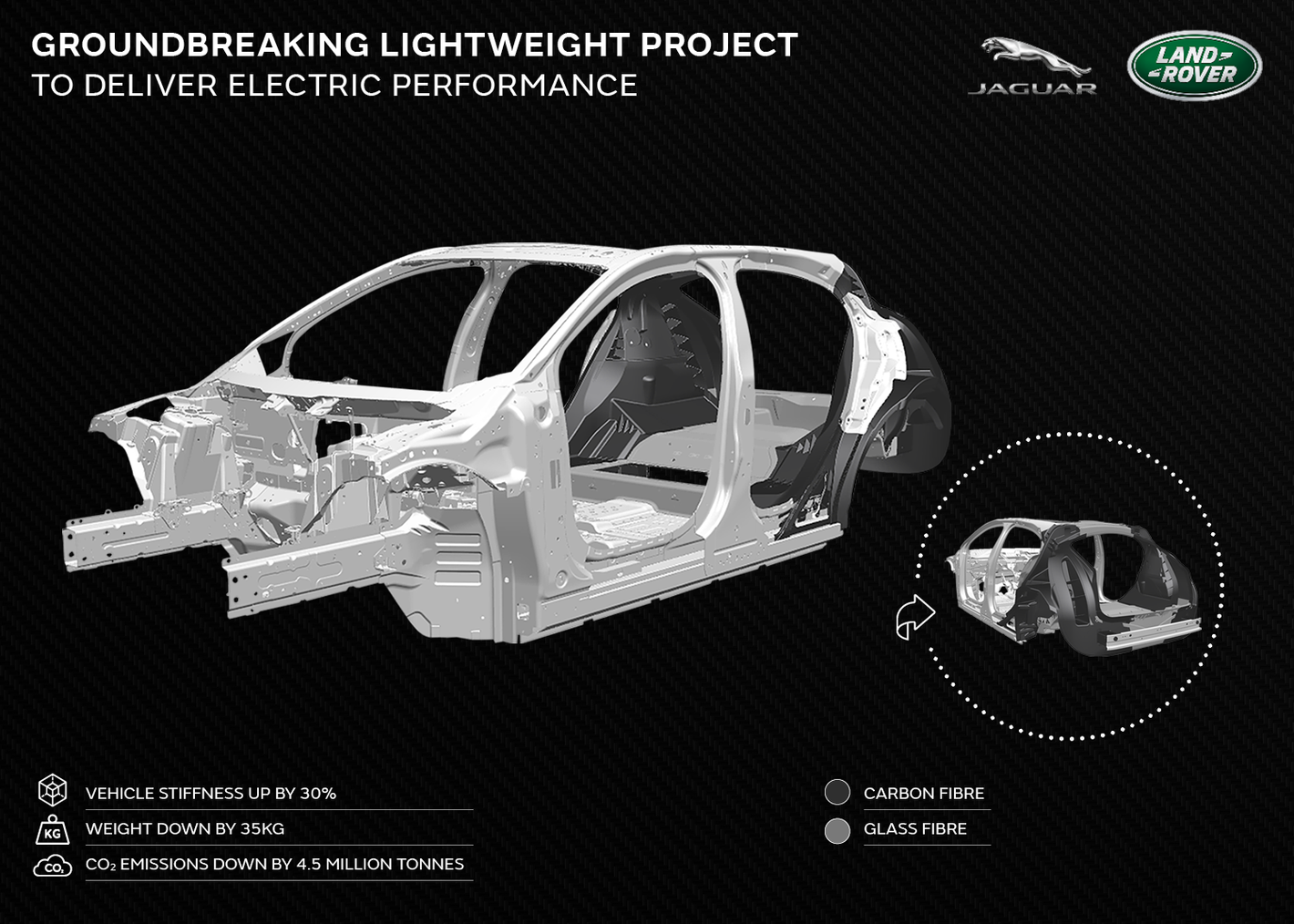

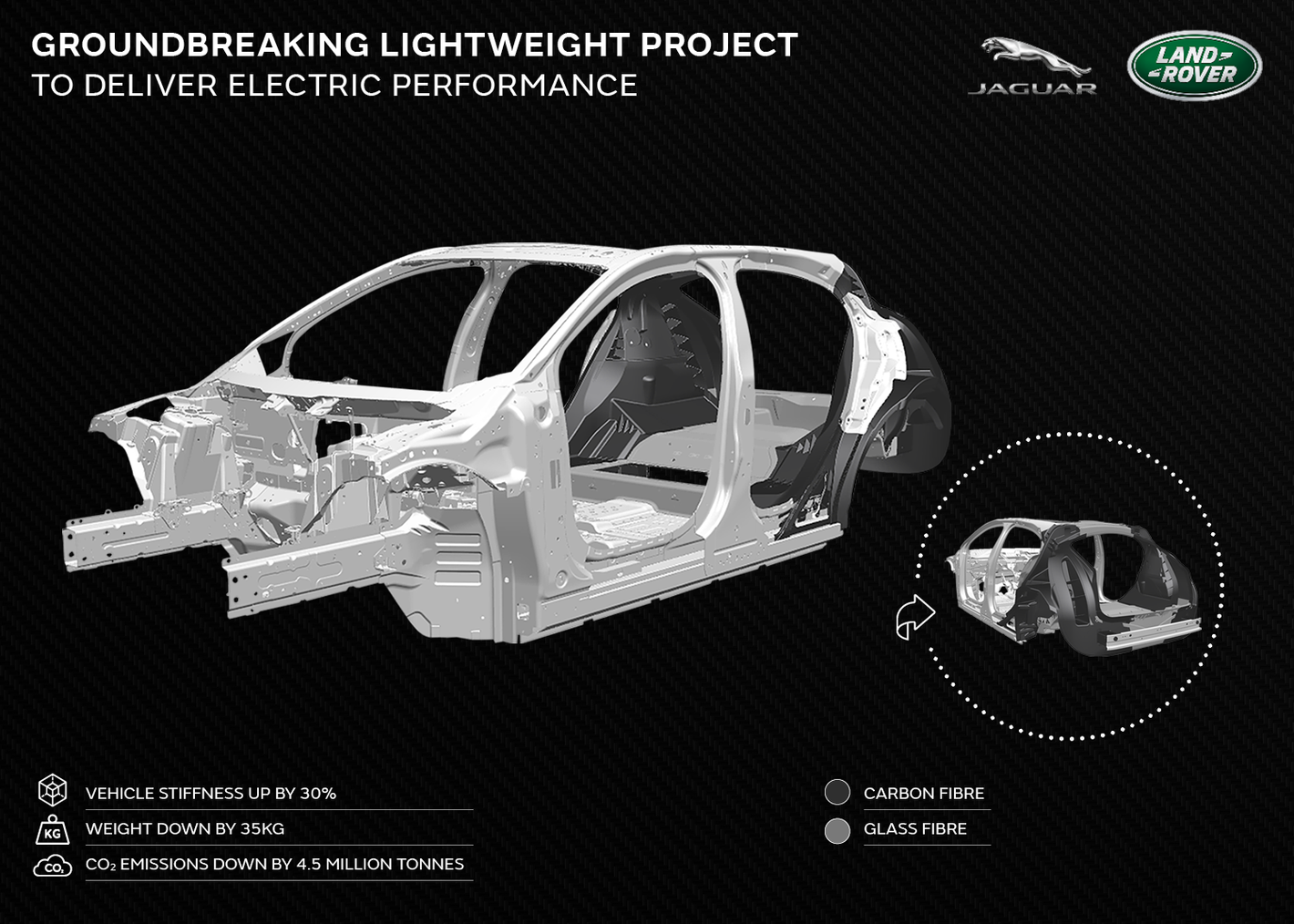

Project Tucana (Consortium, led by Jaguar Land Rover)

Composite skeletal approach for future electric vehicles. 2022 Composites UK & JEC Innovation Awards Winner.

-

Project SOCA (Consortium, led by Jaguar Land Rover)

Next-gen vehicle architecture with a sustainable materials focus. 2024 Composites UK Net-Zero Award Winner.

-

SeaGen Tidal Turbine Repairs

SeaGen was the world's first large scale commercial tidal stream generator.

-

MCMV GRP Repairs and Upgrades

Range of critical Def-Stan approved GRP works. Closely collaborating with the customer in-situ in their shipyard.

-

CF-PEEK Panels for an Aerospace Tier 1

Inclusion and design freedom of ribs. Localised reinforcement to enhance fastener bearing. Design freedom to target isolated structural load case.

-

Luxury Cruise Ship Interiors

Bespoke composite designs manufactured for yachts, movie-sets, and more.

-

Child Aircraft Seats for an Aerospace Tier 1

Aircraft interior solution to full aerospace standards of approval.

-

Pharmaceutical Rotary Drum Filter

Full manufacture of the world's largest known GRP drum filter. 50m2 surface area.

-

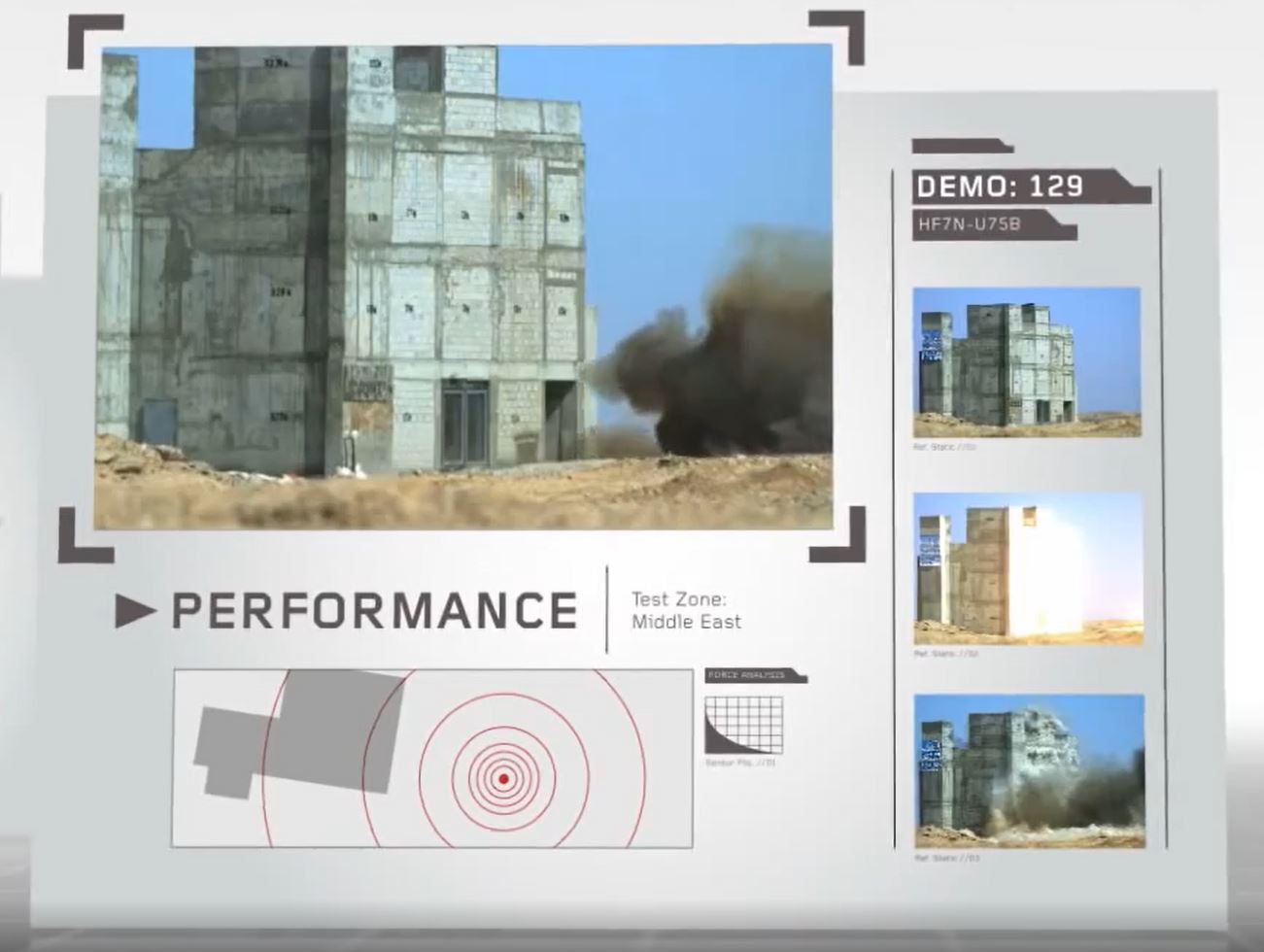

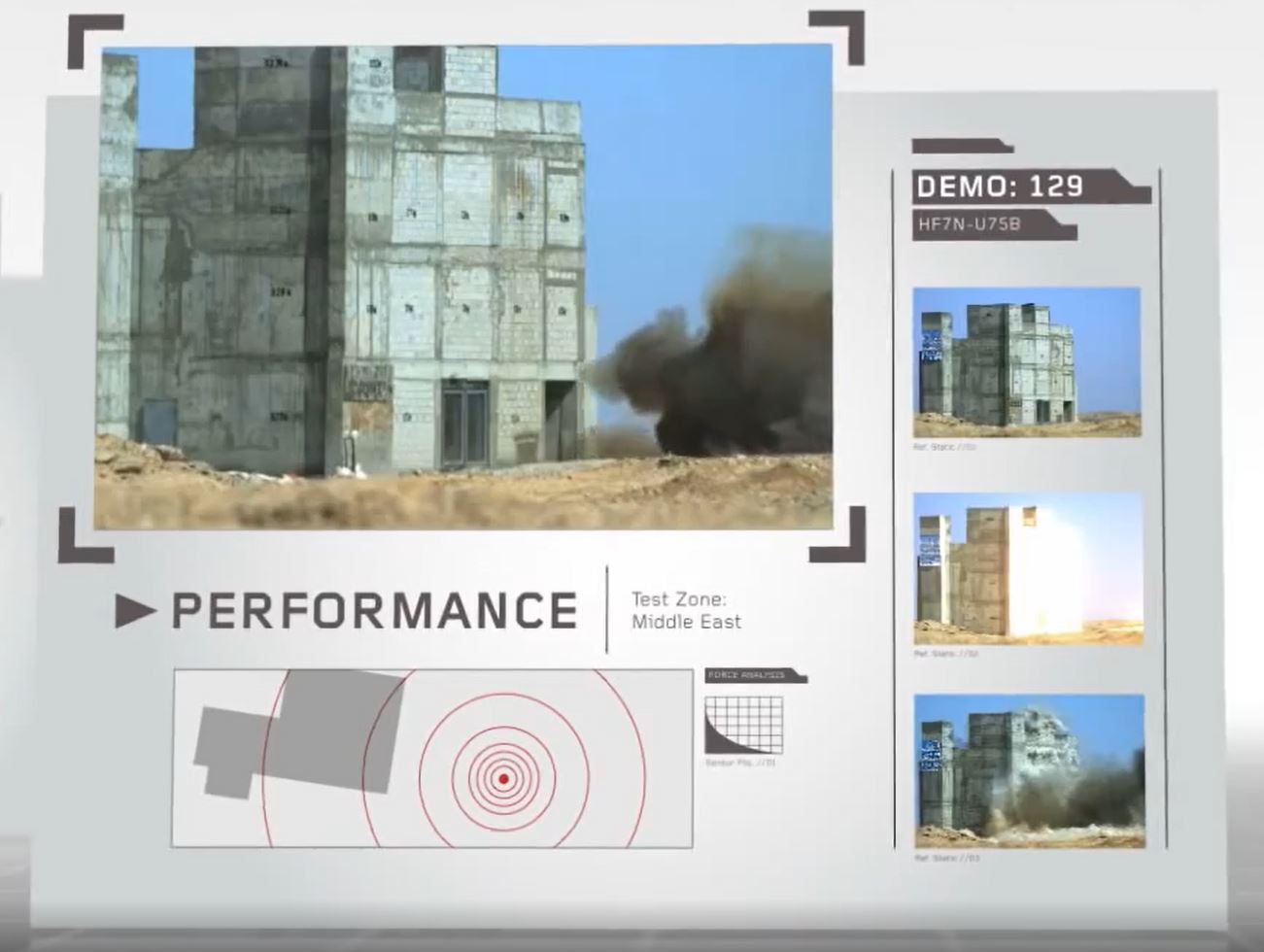

Composite Blastwall for Tecdur® (& More)

Tecdur®. Protecting countless high-security buildings worldwide, including events such as the London Olympics and the 39th G8 Summit.

-

Carbon Fibre Spaceframes

Lightweight, stiff, high-performance spaceframes made from filament wound tubes and 3D printed joints.

-

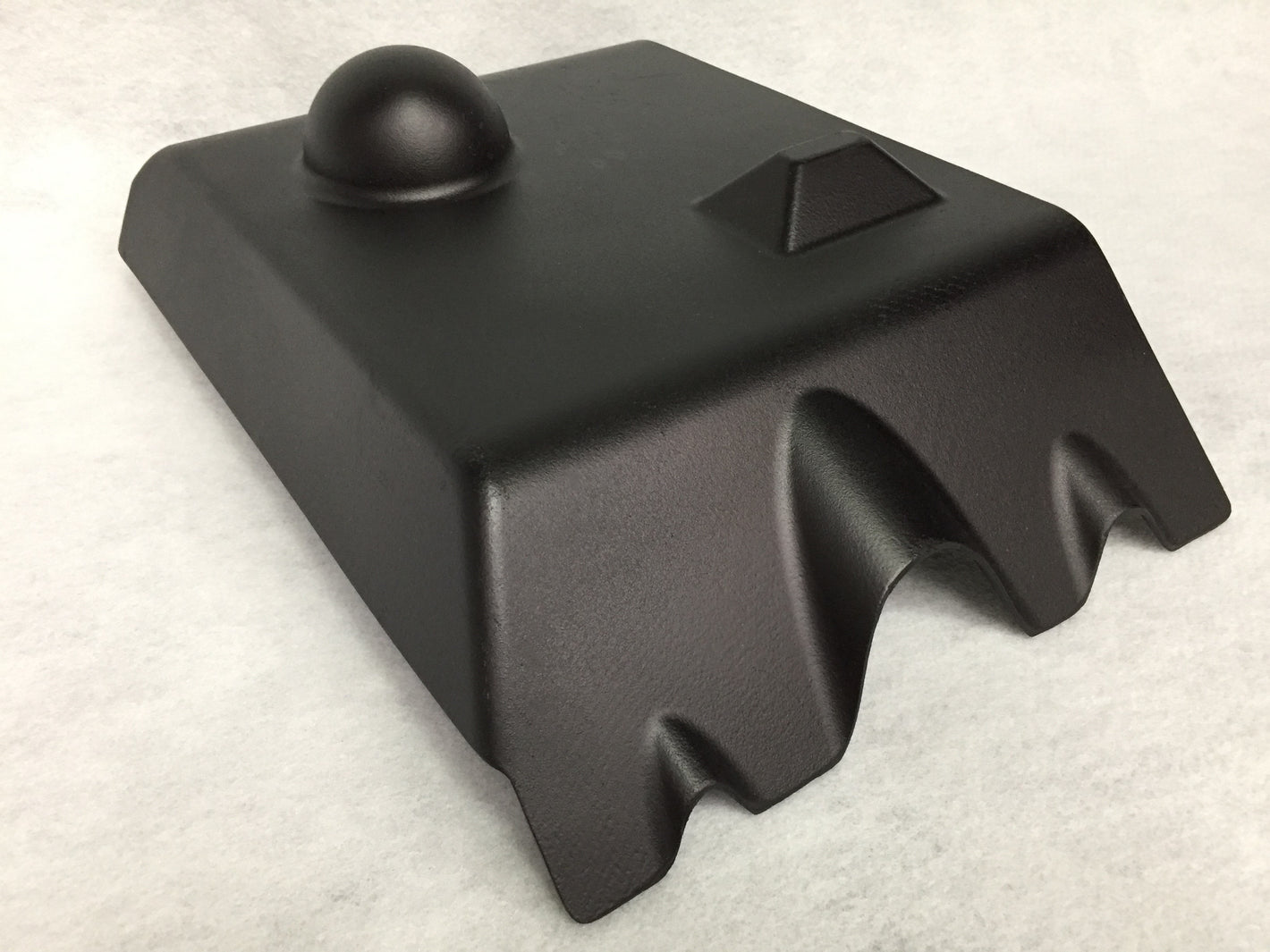

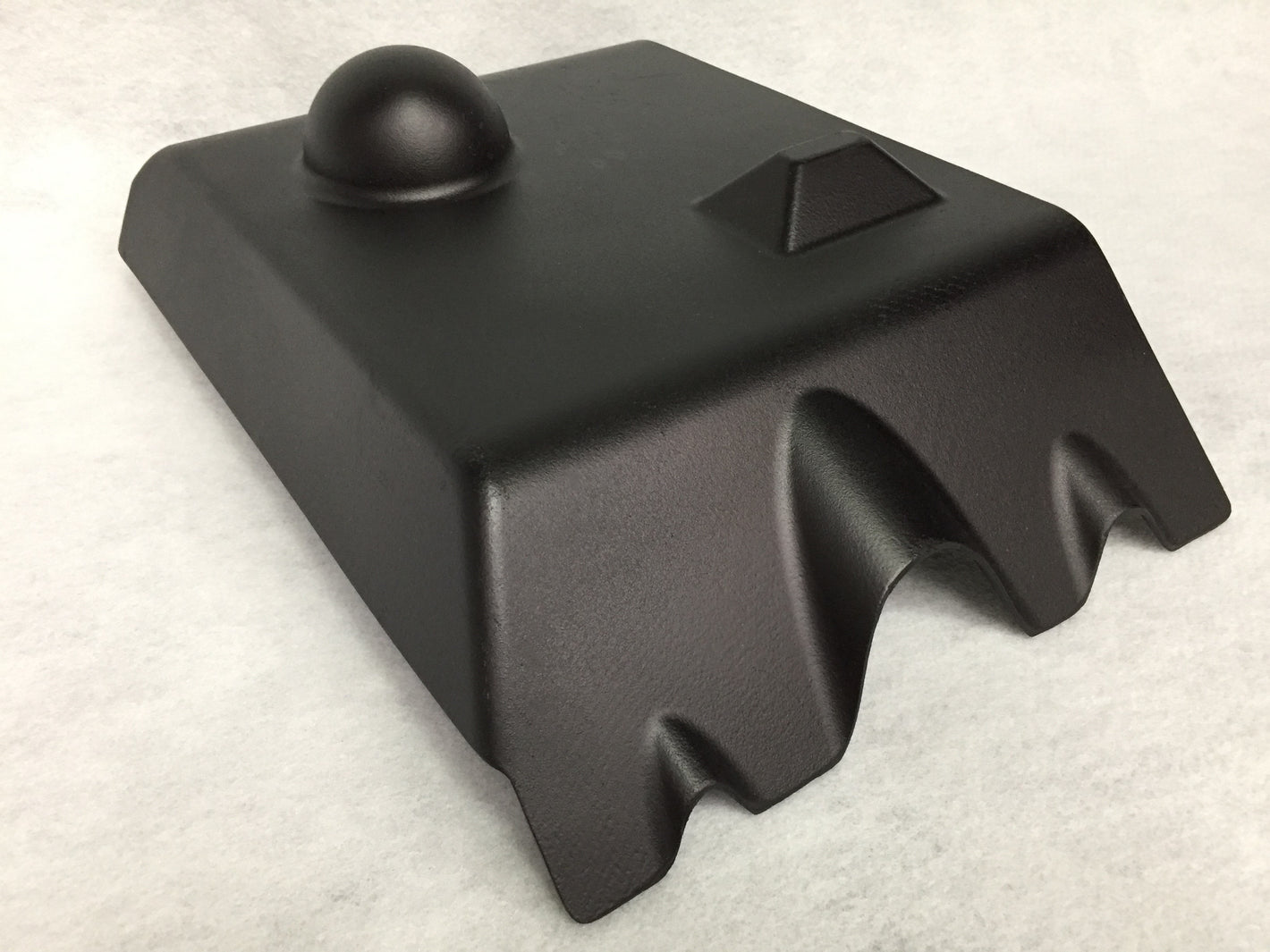

Enhanced Protection Covers

Extremely durable and lightweight, with fast processing. Produced via HPRTM.

-

Next-gen Hydrogen Pressure Vessels

Several R&D projects currently underway with industry-leading partners and research institutions. To be updated soon → Stay posted...

COMPOSITES EXPERTISE

Composites are used everywhere.

Our know-how is transferable between industry sectors.

If you have a specific need please get in touch.

Some more examples we have expertise with include;

- High pressure vessels; suitable for hydrogen fuel tanks, rocket propulsion systems, and gas storage

- Renewables

- Radomes

- Marine antennas

- Railway / Road infrastructure

- High value sporting equipment

- Ballistic protection plates

- Artistic / Film / Movie / Theme park sets

- Fire Smoke Toxicity (FST) and OSU heat release composites

- SMC / BMC automotive parts

- PEEK / PPS / PEI aerospace parts

- Natural-fibre aesthetic panels

- Sustainable composites

- Large scale GRP fabrication / repairs; ships, tanks, and more